Smartpack-Nordic

Palletize and depalletize with mixed sizes of sacks or boxes

SmartPack-Nordic has been developed by us at Robot Nordic. With SmartPack-Nordic software, palletizing and depalletizing is fully automated.

SmartPack-Nordic can set palletizing or depalletizing to mix palletizing. The company’s efficiency is thus increased, and pallets can be saved as several carton sizes are mixed palletized on one pallet. SmartPack-Nordic works for all robots.

With SmartPack-Nordic, the company avoids lost time for programming, as SmartPack-Nordic can be quickly and easily set up to palletize several carton sizes on the same pallet.

With SmartPack-Nordic, production becomes more efficient and your resources will be utilized more optimally.

The most economical or optimal packaging is selected, as SmartPack-Nordic allows you to easily switch between different cartons without any advanced programming. This saves the company time and ensures stable and efficient operations.

Effective packing patterns and mixed palletizing give companies the opportunity to fill the pallets optimally and thus reduce the transport of half-empty pallets.

Flexible palletizing enables companies to better adapt the most optimal packaging size. By selecting the absolutely correct packaging size, the company can reduce overuse of packaging and thus reduce its climate footprint.

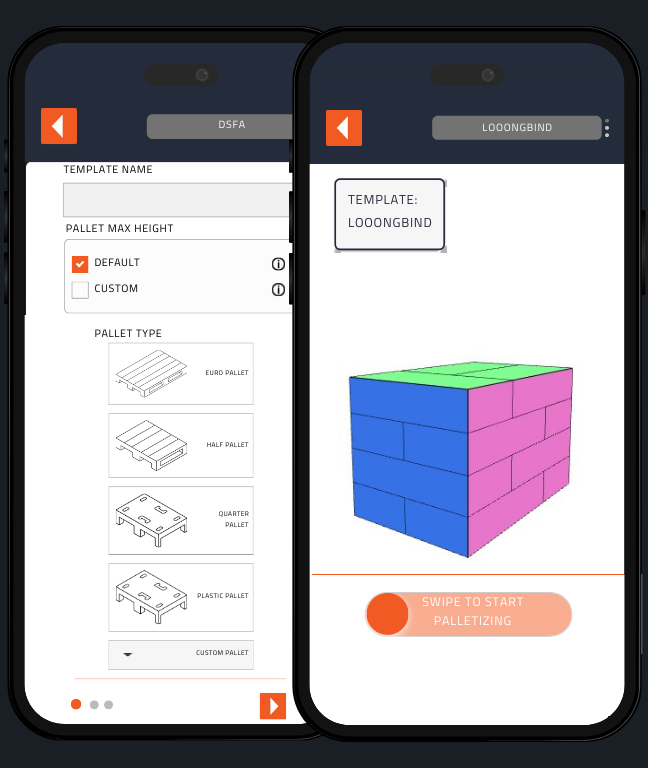

With a few clicks and without programming, the company itself controls preferences for pallet and box size and the software ensures that the palletizing robot packs in the most efficient pattern.

Flexibility is especially important as changes in production, such as new box sizes or something else, have previously meant a stop in palletizing and thus been a bottleneck for the rest of production. This has been the case because changes have required lengthy programming which has resulted in downtime.

SmartPack-Nordic can be connected to all robot types, and is therefore easy to implement with your automation solution, regardless of whether the company already has robots for end of line or wants a completely new solution. We believe this creates flexibility and saves you money.

Regardless of the company’s level of automation, we believe that SmartPack-Nordic will create value for the company by increasing user-friendliness and flexibility at the end of the line, which greatly improves your operational reliability and efficiency.

Here you will find the simple and user-friendly instructions for our SmartPack software (FOR NOW – ONLY IN DANISH):

We have developed SmartPack-Nordic to offer the industry a flexible and user-friendly solution for setting up palletizing and depalletizing. We experienced that industrial customers found it difficult to adjust the palletizing when there were changes in the production line. This resulted in lost time and large costs to get external help to reprogram, for example, new box sizes. With SmartPack-Nordic, palletizing or depalletizing can be set with just a few clicks. The company thus achieves streamlining and improving ergonomics for employees, all while ensuring flexibility at the end of the line.

Flexible production line

This is how palletizing with SmartPack-Nordic works

With a few clicks and without programming, the company itself controls preferences for pallet and box size and the software ensures that the palletizing robot packs in the most efficient pattern.

Depalletizing with SmartPack-Nordic

Efficient, flexible and safe depalletization is important to integrate, especially if the depalletization is one of the first steps in the company’s production line, for example when emptying bags or repacking that delivers to a process facility.

With SmartPack-Nordic, automatic depalletization can be planned down to the smallest detail in an interactive and user-friendly 3D app layout.

How to set depalletization with SmartPack-Nordic

Simply select a new or existing template. With a new template, items are placed using drag and drop. Each product, such as a box or bag, can be adjusted according to weight and volume. In SmartPack-Nordic, a specific grip point can be selected on each individual item whose center of gravity on the item is unique.

SmartPack-Nordic 7 axis palletizing kit set contains:

- 1 pc. Movable module with pallet catch for 2 pallets.

- 1 pc. Holder for Teach Pendant or PLC.

- 4 pcs. Pallet sensors.

- 1 pc. Standard actuator with possibility of palletizing up to 2000 mm.

- 1 pc. Electric vacuum gripper.

- 1 pc. Electric cabinet.

- 2 pcs. Push button panel (start, stop, pause).

- 1 pc. Cable protection kit.

SmartPack-Nordic implemented

Watch a live action video of our unique software implemented on a packaging line at one of our customers.